Curtain Track Systems

OVERVIEW

Tru-Roll manufactures curtain track systems to provide the

following installation options:

- Straight, curved, or serpentine configurations.

- Bi-parting, lap, one-way draw or cascading functions.

- Standard or rear fold draw.

- Motorized, cord operated or walk along operation.

CURTAIN TRACK SERIES OPTIONS

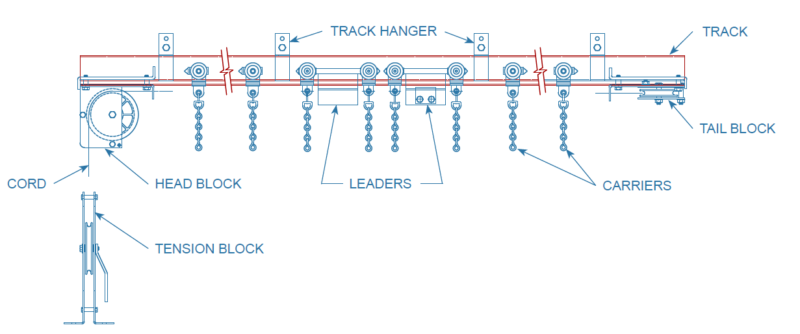

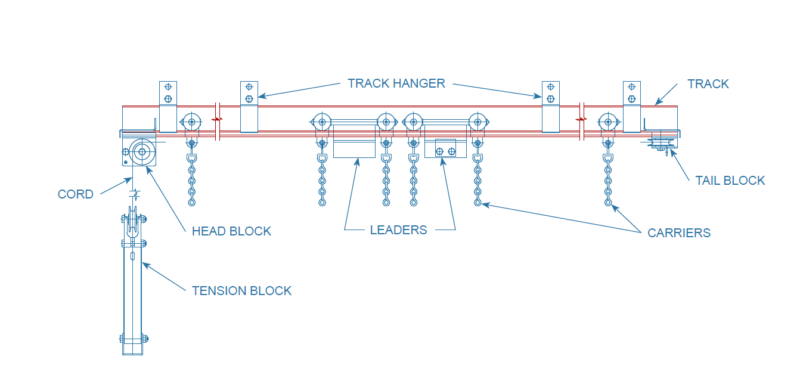

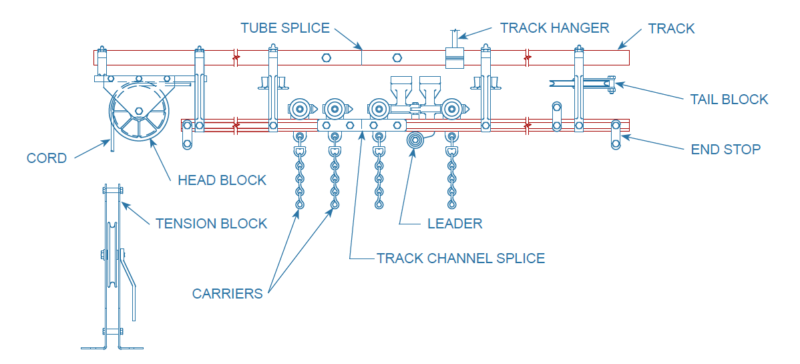

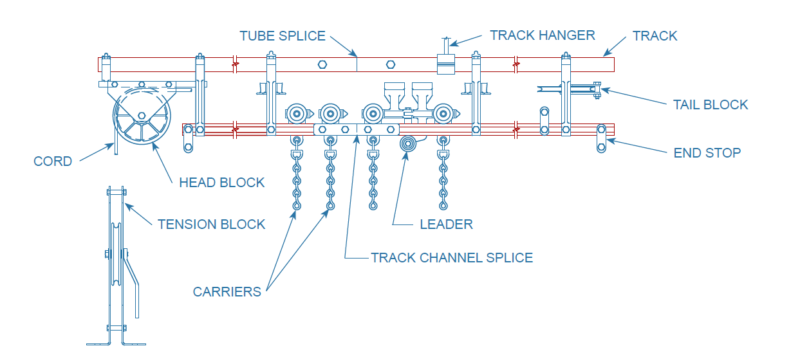

1000 HEAVY DUTY STRAIGHT STEEL TRACK

Straight Track

Available in motorized, cord operated, or walk along formats. These tracks have an exclusive drop flange construction coupled with a fin guided carrier design to ensure quiet, non-fouling and automatically aligning operation.

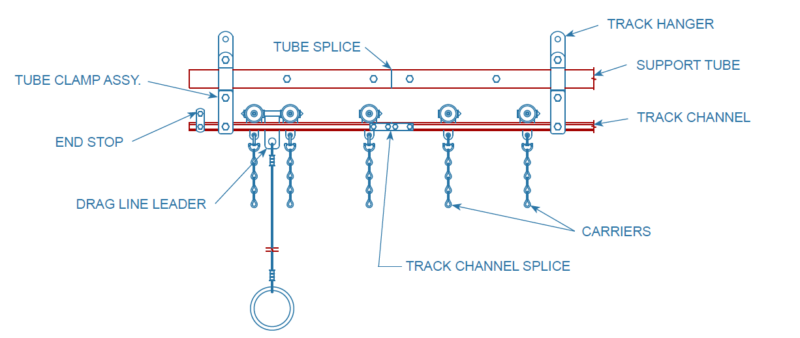

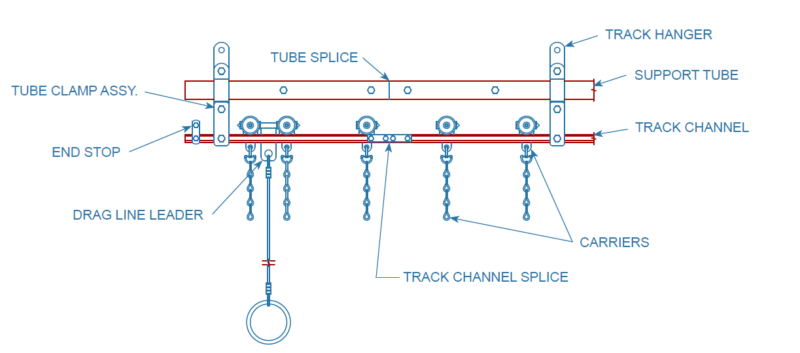

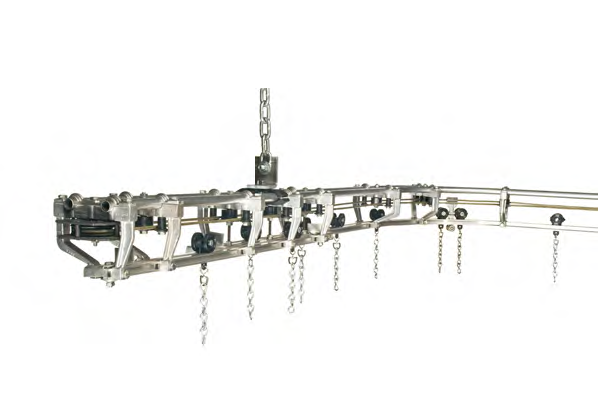

2000 HEAVY DUTY CURVED TRACK

Curved Track

Available in straight, curved, or serpentine sections with standard carriers. Track can be supplied for motorized operation. The parallel strong-back truss construction and aluminum intermediate supports result in an exceptionally strong and durable assembly.

2300 MEDIUM DUTY CYCLORAMA TRACK

Cyclorama Track

Designed for walk along operation, track can be supplied in straight, curved, or serpentine sections. A variety of track switching mechanisms are available to suit specific needs.

2900 LIFT CURTAIN RIGGING

Lift Curtain Rigging

Designed for Braille, Contour and Austrian puff curtains. The system incorporates independent lifting cables to uniformly raise or “sculpt” a drapery to a desired position. Support system may be rigged with a hand winch or fully motorized operation.

PHONE ORDERS ONLY.

Call (626) 599-8337 x 41 for quote.

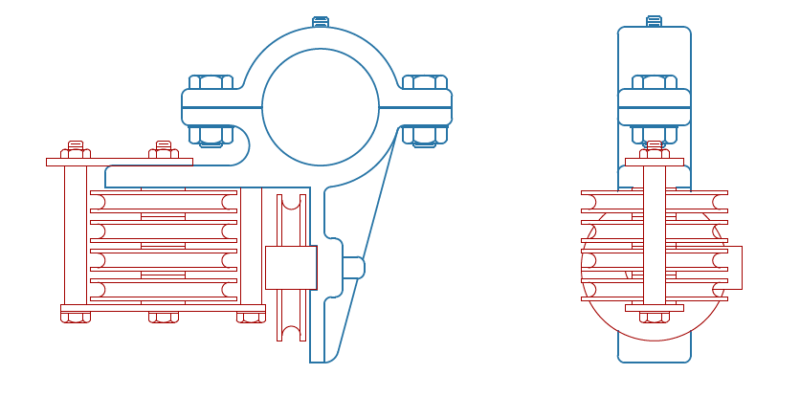

ALL TRACKS

Operating pulleys for all rigged systems consist of mold-formed Nylon 6/6 wheels, integrally molded to a ball bearing hub and mounted on a steel axle. Track carriers for heavy duty systems can be supplied with neoprene tired wheels (for loads up to 25 lbs./carrier) or with ball bearing nylon tired wheels (for loads up to 50 lbs./carrier). Both styles incorporate a fin guided molded nylon body with rubber bumper. Carriers for No. 1000 track may be standard or rear fold (back packing). Carriers for medium duty tracks are fabricated using nylon wheels and feature a one-piece nylon body with integral nylon bumper. Master carriers for all tracks are 4-wheel truck construction, joined by a metal body unit.